Cleveland Torpedo History

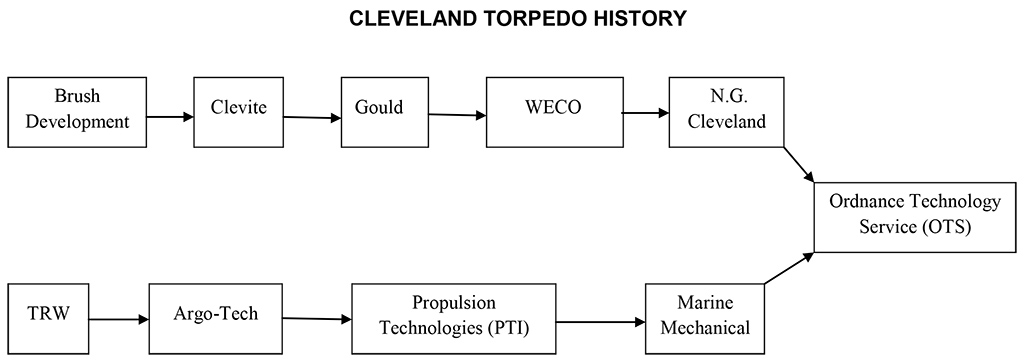

As indicated in the following timeline (Click here for the Cleveland Ohio Torpedo History Timeline), the history of the Cleveland Torpedo Industry dates back to the 1930s with the development of FM Sonar by Brush Development Company (BDC). From this beginning evolved the further development of the MK43, lightweight electric torpedo, by BDC in the 1940s. BDC was eventually acquired as a division of the Clevite Corporation in the 1950s. In the 1960s Gould acquired this product line from Clevite; in the early 1980s this division of Gould was purchased by Westinghouse. Finally, in 1987 Northrop Grumman acquired this division of Westinghouse, until the Cleveland facility closed in 1993. After an attempt to move production to Puerto Rico, an agreement was reached with Ordnance Technology Service to acquire the tooling, forgings and technical data from Northrop and return this technology and manufacturing ability to Cleveland.

As indicated in the following timeline (Click here for the Cleveland Ohio Torpedo History Timeline), the history of the Cleveland Torpedo Industry dates back to the 1930s with the development of FM Sonar by Brush Development Company (BDC). From this beginning evolved the further development of the MK43, lightweight electric torpedo, by BDC in the 1940s. BDC was eventually acquired as a division of the Clevite Corporation in the 1950s. In the 1960s Gould acquired this product line from Clevite; in the early 1980s this division of Gould was purchased by Westinghouse. Finally, in 1987 Northrop Grumman acquired this division of Westinghouse, until the Cleveland facility closed in 1993. After an attempt to move production to Puerto Rico, an agreement was reached with Ordnance Technology Service to acquire the tooling, forgings and technical data from Northrop and return this technology and manufacturing ability to Cleveland.

The primary product line Gould was known for was the Heavyweight MK48 torpedo. Their involvement started with the Mod 0 and continued through the development of the Mod 6 version, with additional work in such programs as the CBASS Sonar System, Noise Deadening Program Development, and a host of other programs. Other product lines included the MK50 torpedo, the MK46 torpedo (limited production), and other products that required harsh environment or excessive engineering expertise. The key to this Cleveland facility was their strong engineering expertise in both electro and mechanical environments.

In the mid 1960s the US Navy was looking for a firm to take over production of the Lightweight MK46 torpedo from Aerojet Corporation, which did early engineering development. The Navy chose Honeywell Corporation, of Hopkins, MN. Honeywell’s expertise was in electronics and was considered the Original Equipment Manufacturer of the MK46. However, as Honeywell did not have expertise in the mechanical operations of the Fuel Tank and Afterbody they teamed with TRW Corporation, a company with strong mechanical capabilities. From the 1960s through the early 1990s TRW was the manufacturer for the majority of the MK46 propulsion systems. TRW’s expertise was so critical they developed their own Technical Data Package for the Fuel Tank and Afterbody production which met and exceeded the current government production drawings. Thus, it is important to know that the MK46 propulsion system was manufactured with proprietary production drawings, by TRW, not Honeywell, the often-listed OEM for the lightweight torpedo.

In the early 1990s when full scale production of the MK46 torpedo ceased, TRW divested the torpedo and aircraft pump divisions to Argo-Tech Corporation, with the torpedo Product area known as Propulsion Technologies Inc. (PTI). Eventually this became part of Marine Mechanical Corporation (MMC), and when spares support was no longer cost-effective to MMC, all inventory and technical data was transferred to Ordnance Technology Service.

From the 1960s through the early 1990s these two company chains were the backbone to the lightweight and heavyweight torpedo development and production industry. Located within 5 miles of each other they often traded and competed product lines, and personnel, when the US Navy decided they required dual sourcing. TRW manufactured heavyweight MK48 Mod 4 Fuel Tank and Afterbody when Hughes Electronics was chosen as a second source for the heavyweight. Likewise, Gould manufactured a small quantity of complete MK46 torpedoes in the 1980s. Both firms also worked on the MK50 lightweight SCEPS (lithium boiler) propulsion system. In addition, with both large manufacturer chains located here, many of the support manufacturers, both machine and electronics shops, were also located in the Cleveland area.

Presently, OTS continues to carry the Cleveland Legacy of its predecessors by maintaining key components to the Torpedo Program that include but are not limited to:

- Engineering Technical Data Packages and Manuals from the initial designs

- Proven processes and procedures that note the intent of each application within the developmental stages

- Inventory, crucial to replicating unique historical procedures

- Engineering consulting contacts

- Tooling and Gauges

Most valuable of these is the on-call technical expertise and review by engineers from our predecessors, Gould, TRW, and the numerous support companies that are still located here in the Cleveland area. Retaining this attested intergenerational knowledge base has proven to be an essential asset to the Program as a whole. In particular with the advent of Program restart in both the heavyweight and lightweight Programs, this knowledge is crucial to the mitigation of obsolescence issues and the integration of the procedures of the past.